Autodesk Powermill

Professional, high-speed and multi-axis CAM software

- PowerMill; It is an advanced CAM software that excels in machining large or complex parts where quality, precision and manufacturing efficiency are of paramount importance. You can import data from virtually any CAD program into PowerMill, including surfaces, solids or STL meshes, and calculate high quality 3- and 5-axis NC codes using highly efficient CAM algorithms. PowerMill; It combines highly effective algorithms with exceptional levels of control used to create, manage and optimize toolpaths to produce the most complex parts.

Advantages of using PowerMill

Access a vast library of strategies in PowerMill. Reduce programming times with rapid toolpath calculation.

- Easy, fast usage interface,

- Strong strategies, super surface qualities,

- Super fast calculation with multi-processor support and 64 bit, Modern Windows interface,

- Widespread support, Internet training videos,

- Easy to find operators due to prevalence, easy staff training,

- Provides fast machine processing times, delays additional machine needs,

- You do not have to buy new software for future 5-axis investment, change your existing software and personnel.

Subscription benefits to PowerMill

- Opportunity to start at a much lower cost of permanent license with low initial cost

- Reducing business risks with low initial cost, – Tax reduction up to 20% by showing costs, – Not being affected by personnel changes,

- Responding instantly to the changing number of machines and personnel, only as needed do not pay, - no annual costs, such as maintenance and support services,

- Always up to date study

- Continuous able to get Technical support.

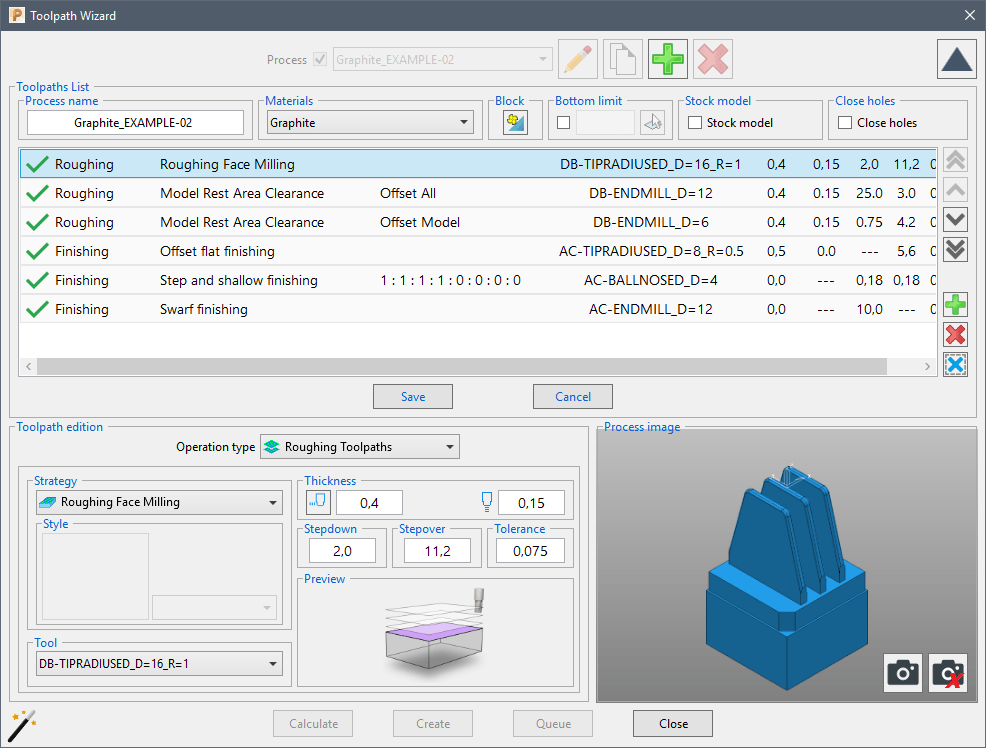

PowerMill Electrode

- Autodesk PowerMILL CAD solution provides your manufacturing modeling needs very quickly and easily with its advanced tools and direct modeling capabilities. It automates and speeds up the modeling and electrode preparation processes of CAM operators.

- With the Autodesk PowerMill electrode solution, the PowerMill CAM software works as you teach and calculates the rough, semi and finishing machining of the electrodes you prepared with PowerShape, according to their shares, and presents them together with the process sheets. In fact, if you wish, it provides and reports the quality control works of these without dismantling the work on the workbench.

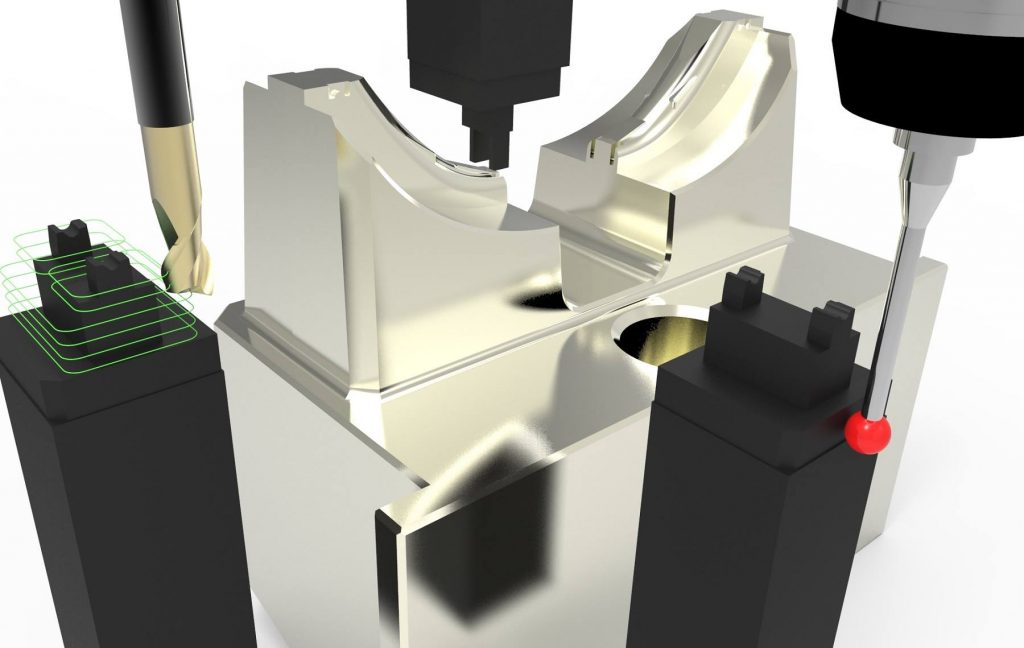

PowerMill Robotics

- Fast, precise, flexible robot programming, simulation and validation. Advanced features of PowerMill® software; By facilitating 3- and 5-axis programming, simulation and verification processes, it enables manufacturers to get more efficiency from machining, additive and hybrid manufacturing machines, and facilitates processing with robots, one of the advanced production solutions. Autodesk PowerMill Robot software is used in the following areas;

- Stone, marble and wood shaping, milling

- Foam and resin processing

- Edge and deburring (Trimming)

- Laser and plasma cutting

- laser coating

- Polishing and grinding

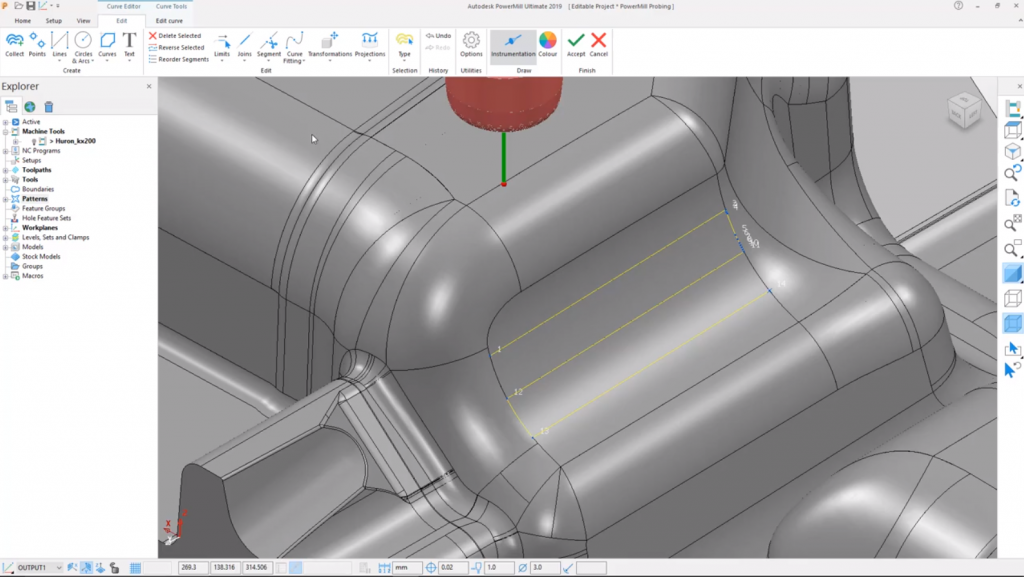

PowerMill Probing

- Fast-evolving technology – probes mounted on spindle. As it is known, the use of probes on the workbench is generally in the direction of part reset. This allows for precise machining and part setup and is an important feature that is widely used.

- Another application area of probes is Verification. In other words, it is the control of the part after processing. With the help of macros that can be found on the bench control unit, measurement controls of simple geometric elements such as boxes and circles can be provided. More difficult is the control of complex 3D shapes, which requires comparing the differences with the CAD model.

- PowerMill Probing enables companies that process complex CAD models to make precise 3D measurements. This was previously provided with the PowerInspect OMV software, but milling and measuring issues had to be driven with separate software. Now the 3D “Surface measurement” capability is available in a single interface with the PowerMill Ultimate version.

PowerMill Optinc

- It is a plug-in developed to work with Autodesk Powermill CAM software. With over 100 features to support the programming process, its main goal is to allow CNC Programmers and Process Engineers to have more time for new technologies and more efficient processes.

- Repetitive processes that do not add value to the process are performed automatically, quickly, easily and much more efficiently by Optinc.

- Optinc shortens toolpath creation and editing processes by up to 90%. It eliminates repetitive work and mistakes that can be made in them, and accelerates it. With Optinc, you can reduce your electrode preparation processes to seconds, and work easily and error-free with multiple electrodes with pallet support.